Industrial agitators, often overlooked in the grand machinery of manufacturing, are the unsung heroes that play a pivotal role in various industries. Beyond mere stirring, these devices are essential for achieving consistency, homogeneity, and efficiency in processes ranging from chemical production to food processing. In this exploration, we delve into the multifaceted world of industrial agitators and unveil their indispensable contributions.

Mixing and Blending:

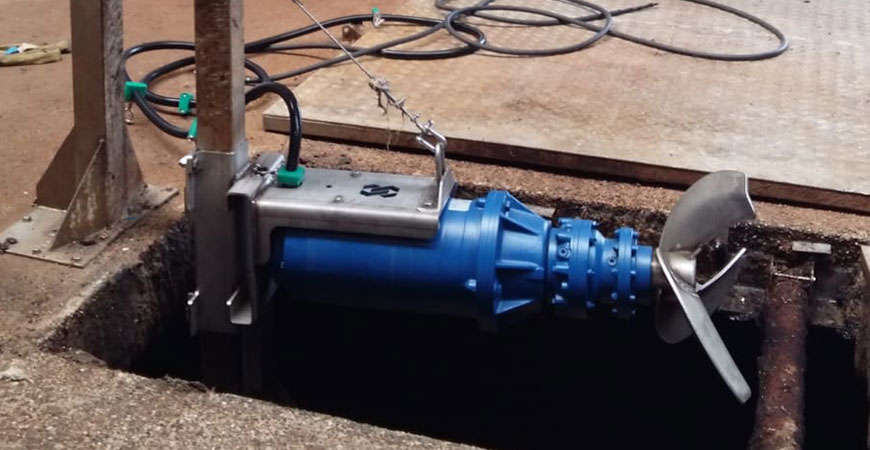

At its core, the primary function of industrial agitators is mixing and blending. These devices employ different mechanisms such as rotating blades, paddles, or impellers to thoroughly mix various components. In chemical manufacturing, for instance, precise mixing is critical for achieving the desired chemical reactions. In the food industry, agitators ensure that ingredients are uniformly distributed to create consistent products. Without them, we would encounter an array of inconsistencies in the products we rely on daily.

Temperature Control:

Beyond mixing, agitators also play a pivotal role in temperature control. In many industrial processes, maintaining a specific temperature range is crucial for product quality and safety. Agitators can be equipped with heat exchange systems to either heat or cool the mixture, ensuring that it remains within the desired temperature parameters. This capability is indispensable in industries like pharmaceuticals, where the slightest temperature deviation can compromise the efficacy of medications.

Homogenization:

Certain industries require not only mixing but also complete homogenization of substances. Industrial agitators excel in this aspect by breaking down particles and ensuring uniform distribution. The dairy industry, for example, relies heavily on agitators to homogenize milk, preventing cream separation and creating a consistent product. Similarly, the cosmetics industry employs agitators to homogenize lotions and creams, ensuring a smooth and even texture.

Suspensions and Dissolutions:

In the pharmaceutical and chemical industries, the ability to create stable suspensions and dissolutions is paramount. Agitators facilitate the dissolution of solids into liquids or the suspension of solids in liquids, enabling the production of medicines, paints, and other products. Without agitators, these processes would be time-consuming, inefficient, and prone to inconsistencies.

Gas Dispersion:

In addition to working with liquids and solids, industrial agitators are also adept at handling gases. They can be used to disperse gases into liquids, enhancing reactions in applications such as wastewater treatment, fermentation processes, and chemical synthesis. By promoting better contact between gases and liquids, agitators increase reaction rates and improve overall process efficiency.

Preventing Sedimentation:

In many industries, settling and sedimentation can lead to separation of components over time. The agitadores prevent sedimentation by constantly agitating the mixture, keeping particles in suspension. This is vital in the mining industry, where agitators help extract valuable minerals by preventing them from settling at the bottom of tanks.

Customization and Innovation:

The world of industrial agitators is not stagnant it continues to evolve. Engineers and manufacturers are constantly innovating to design agitators tailored to specific industries and processes. Whether it is creating agitators resistant to corrosive chemicals, developing more energy-efficient models, or incorporating advanced control systems, customization and innovation are driving forces in this field.